The Challenge

The 75 MGD Central Valley Water Reclamation Facility (CVWRF) is one of the few Utah facilities to use anaerobic digester gas/natural gas mixture to generate about 85% of its electricity needs in a cogeneration system. The digested biosolids, once dewatered, produces a liquid stream with a very high ammonia concentration. This high ammonia liquid stream (ie. centrate), needs to be treated before it’s returned back to the front of the plant to reduce the stress to the mainstream process and help meet a seasonal ammonia permit limit of 3.6 to 3.7 mg/L.

The plant researched various technologies for treatment of the centrate and determined that deammonification was the best solution. CVWRF established a set of criteria and a scoring mechanism to include, but were not limited to the following: reliable and stable; resilient and robust; easy to operate and maintain; cost effective; easy to expand for future capacity increases and THP adoption, etc.

The Solution

Veolia’s ANITA™ Mox anammox system was selected based on a comprehensive evaluation and staff visits to various deammonification systems.

Once selected, Veolia assisted CVWRF with process design and equipment selection before the contract was assigned to a contractor for construction.

Process Description

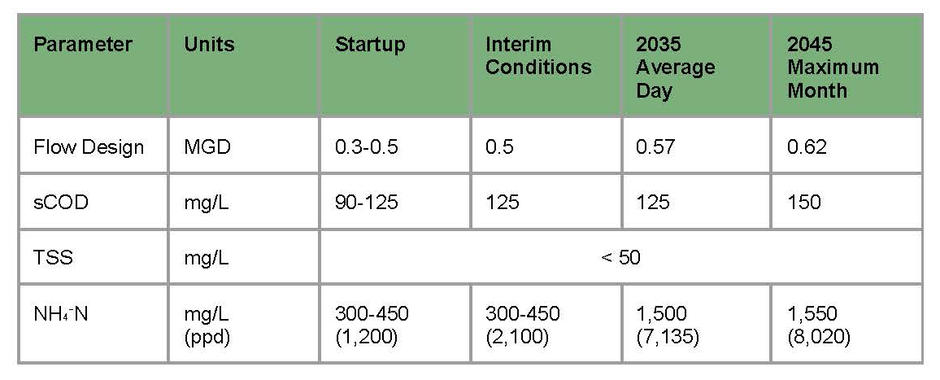

The ANITA Mox system consists of two new circular reactors in parallel. The reactors are designed to have sufficient volume to provide treatment for future design flow and load. The system components include AnoxK™ 5 media, AnoxK mixer, media retaining screens and custom medium bubble aeration diffusers. The initial media volume fill of one reactor is sufficient to treat the initial available centrate load. As centrate flow and load increase, more media can simply be added with the rest of the system equipment in place. Air for the ANITA Mox system is supplied via dedicated blowers, as required by the plant. The design parameters for the system are shown below.

Results

The system startup began in late August 2023. It took less than seven weeks to reach full design load and removal rates with the help of the proper amount of seed media. From August 2023 to March 2024, the ammonia removal rate averaged 83% and the TIN removal rate averaged 75%. The simplicity and robustness of the process and the performance of the system meets CVWRF’s expectations.

The Client

The Central Valley Water Reclamation Facility (CVWRF) is located in South Salt Lake City, Utah. The CVWRF serves five Improvement Districts and two cities that have been increasingly growing and collects between 50 and 60 MGD of wastewater each day. The effluent from CVWRF is discharged to Mill Creek and Jordan River.

Key Figures

Plant Design Flow Rate: 75 MGD

Average Flow Rate: 50-60 MGD

Centrate Flow Rate: 0.3 - 0.85 MGD