Veolia Water Technologies provides expertise and experience in water and wastewater treatment for all aspects of the oil and gas sector.

Water is vital to the production process at oil and gas facilities. Veolia Water Technologies understands the issues related to water and wastewater management and has experience in helping customers achieve their goals to:

- Lower the cost of production

- Minimize risks associated with maintenance downtime

- Ensure compliance with environmental regulations

- Extend the life of your systems

- Expand your treatment capacity

Applications

- Biological Wastewater

- Clarification/Softening

- Degassing Water

- Evaporation & Crystallization

- Filtration

- Flotation

- Ion Exchange

- Membrane Systems

- Metals Removal

- Odor Management

- Process Water

- Reuse & Reclaim

- Sludge/Biosolids

- Utility Water Treatments

- Industrial Wastewater Treatment

- Water Treatment Chemicals

- ZLD Solutions

Services

Water is a major component in all phases of oil and gas production Veolia provides sustainable management solutions for handling and treating produced water, and for production of water injection. With innovative technologies and a long history of serving the industry, Veolia provides solutions both onshore and offshore for:

- Enhanced oil recovery (EOR)

- Treatment of injection water

- Treatment for beneficial reuse of produced water

- Treatment of produced water for surface discharge

- Treatment of produced water from gas production

- Water treatment for the midstream sector: Liquefied natural gas (LNG), Floating LNG, etc.

Produced Water Treatment Solutions for SAGD Production

Evaporation technology is an accepted method of treating oilfield produced water from enhanced oil recovery operations such as SAGD and CSS. This thermal process provides high-quality distillate as feed water for steam generation and allows the flexibility of using either traditional OTSGs (once-through steam generator) or drum-type boilers.

Veolia Water Technologies has developed process technology for cost-effective treatment of produced water containing high levels of silica and other scaling components. This technology, called the Silica Sorption Process, is designed specifically for produced water treatment. The scaling tendencies and organics levels of produced water make it a challenging application.

Deoling Technology

Veolia provides highly effective deoiling systems for produced water. This includes both mechanical induced gas flotation (IGF) and walnut shell oil removal filter (ORF) technology.

The AutoFlot® IGF, coupled with Power Clean® walnut shell ORF systems, provides a process train that effectively reduces free oil and solids by 90-95% with maximum inlet concentrations of 300 mg/l of free oil and less than 150 mg/l of total suspended solids.

Case Study - Shell Pearl GTL

Our partnership with Shell and Qatar Petroleum in the Pearl GTL site enabled the installation of advanced technologies to reduce its environmental impact – with our zero liquid discharge (ZLD) technology completely manages effluent and process water in a closed circuit. Effluents and process water are fully managed in a closed circuit. The wastewater treatment capacity reaches 45,000 m3 per day.

Raw water treatment

Water is a major issue during downstream oil and gas processes. A quality product is essential for the smooth running of refining processes. Therefore, we provide our customers with raw water that is healthy and safe. Raw water treatment applications include:

- pre-treatment of process water;

- production of process water to be fed to boilers and to be used as cooling water; and

- production of demineralized water for the dilutions that are necessary in petrochemical processes.

Wastewater treatment

Veolia Water Technologies treats wastewater generated by oil and gas industrial processes during downstream activities in them. Our mission consists in treating wastewater, rainwater and industrial effluent before it is reused or discharged. Our treatment process aims to purify the water of elements that are toxic to the environment. Such pollutants may be of any kind. They include, for example hydrogen sulfide, DOC, ammonia, hydrocarbons, oils, phenols, DBO, mercury, cyanides, selenium, and chlorides.

Groundwater remediation

To remove dissolved and dispersed hydrocarbons in water, Veolia Water Technologies uses Macro Porous Polymer Extraction (MPPE) water treatment technology. This patented technology has a success rate of 99.9999%. Particularly effective, this technique has many advantages. It is a process that generates little noise but is also economically advantageous because it is inexpensive and does not require the addition of chemicals. We offer an automated, remote-controlled, and fully guaranteed process.

Water recycling and reuse

At Veolia, we safeguard water and enhance its recycling value by optimizing its potential for reuse, through our portfolio of 350 proprietary technologies that cover water issues, in particular during downstream industrial operations. By recycling wastewater, we minimize the need for freshwater. Veolia offers a full range of technologies as well as technical solutions for wastewater treatment and processes to maximize water reuse.

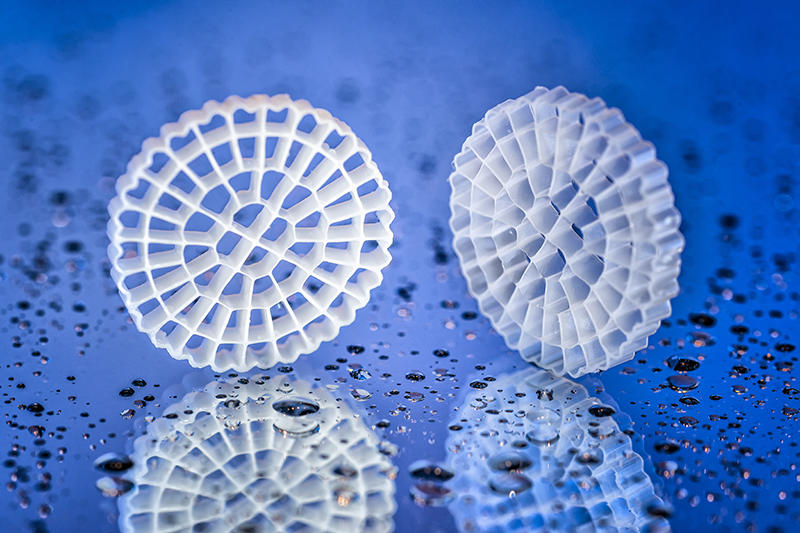

Case Study - AnoxKaldnes™ MBBR Proves Effective at Asphalt Refinery

Technology: AnoxKaldnes MBBR Technology

Location: Northeastern United States

The refinery needed to upgrade the wastewater treatment system to prepare for expected changes brought about by the use of a new crude feedstock. The new wastewater was predicted to contain elevated concentrations of TDS and conductivity.

Veolia Water Technologies supplied an AnoxKaldnes™ Moving Bed Biofilm Reactor (MBBR) treatment system to reduce the BOD and ammonia in the effluent at an asphalt refinery in the Northeastern US. Veolia provided the process and detailed design engineering to size the MBBR system, specifying all components in chloride-resistant materials of construction because of the high chloride concentration of the wastewater (3,500 mg/l). Equipment included the MBBR media, blowers, instrumentation and custom-designed aeration basin laterals and effluent sieves fabricated from Zeron 100 and 2507 SS. Veolia also provided start-up assistance and process engineering support that enabled the biological system to successfully acclimate to the high-TDS wastewater.

Production companies face challenges related to cost structure swings, asset protection, safety, climate, geographic hazards and environmental constraints across the diverse conditions they operate in.

Veolia offers unique solutions that drive down lease operating expenses and minimize problems that threaten well profitability. We integrate chemical technologies, equipment systems, and robust service support to provide a balanced approach to solving customer problems and maximizing production efficiencies. We collaborate with your experts to optimize chemical usage, objectively measure our performance, and ensure that we positively impact your balance sheet economics.

Veolia’s comprehensive line of Hydrex performance chemicals provides effective protection against your stimulation, completion, deep well injection, midstream and pipeline challenges.

Hydrex Chemical Technologies

Our operational culture drives the continuous improvement which separates Veolia as a leader in all its business interests. Our Hydrex technologies deliver the results you expect at your well sites to support your business objectives.

We are aligned with your needs to operate efficiently and cost effectively, while producing a quality product. Through our Hydrex technologies, our goals are to maximize your production efficiency rates, protect your asset integrity and maximize life cycle costs while assuring that your overall lease operating expense is minimized.

- Scale & Corrosion Inhibitors

- Chemical Sensors for Verification

- Bacterial Control

- H2S & O2 Scavengers

- Iron Sulfide Dissolvers

- Hydrate Inhibitors

- Emulsion Breakers

- Foamers & Specialty Surfactants

- Paraffin & Asphaltene Deposit Control

- Calcium Naphthenate Inhibitors

- Produced Water Recycle & Reuse

- Odor Abatement

- Friction Reducers & Cross Linking Agents

Actiflo® High-Rate Clarifier/Softener

Small-footprint technology in which water is flocculated with microsand and polymer to increase settling velocity for the removal of more than 99% of TSS.

Learn More

HPD Evaporation & Crystallization

Systems are effective in concentrating wastewater streams to produce high-quality distillate for reuse and volume reduction. Unique processes developed for SAGD and shale gas applications are effective for produced water containing high levels of TDS.

Learn More

CoStrip®

Degasifier offers an efficient alternative to vacuum degasification by using enhanced flotation technology with natural gas or nitrogen to strip dissolved gasses such as volatile organic compounds (VOCs) from produced water.

Learn More

Power Clean

Nutshell filters are effective for the removal and treatment of hydrocarbons and suspended solids from produced water applications.

Learn More

Whittier - Ion Exchange Softening

High specification Strong Acid Cation (SAC), Weak Acid Cation (WAC) or a combination of both in series, or a multi-step process of softening with other water treatment technologies for produced water treatment.

Learn More

Hydrotech™ Discfilters

Filtration technology that uses woven media panels to remove suspended solids > than 10 microns

Learn More

Multiflo® High-Rate Softener

Proprietary softening process that incorporates chemical precipitation with sludge thickening to produce an effluent with low concentrations of scale-formers and a highly concentrated sludge that can be easily dewatered.

Learn More

AnoxKaldnes™ MBBR (Moving Bed Biofilm Reactor)

High-performance aerobic wastewater treatment technology engineered to effectively remove nitrogen and BOD/COD

Learn More

Featured Resources

Oil & Gas Technology Brochures

Meet Our Team

Albert Low

VP of Sales, Whittier Filtration

Los Angeles, CA

Chance Kucera

Business Development Manager, Oil & Gas Services

San Antonio, Texas

Dave Oliphant

VP of Business Development - Heavy Industry

Canada

Steve Michaluk

Sr. Sales Manager, HPD® Evaporation and Crystallization

Western Canada