Veolia Water Technologies offers extensive onsite and laboratory analytical support.

Consistent laboratory testing is critical to characterizing water and wastewater for treatability, as well as providing early indications on the overall performance of an existing system. Veolia’s in-house laboratory field analytical services include:

- Basic field testing

- Comprehensive water and wastewater characterizations

- Gas chromatography

- Physical / Chemical testing

- Sludge analysis

- Microfiltration membranes testing

- Biological treatability

- Bio-methane potential (BMP) testing

- Biomass activity analysis

- Anaerobic chemical toxicity testing

- Evaporation & crystallization testing

- Research and development

- System troubleshooting

- Predictive modeling & simulation

- Scale & corrosion studies

- Failure analysis

- Microbiological efficacy studies

- Laboratory pilots

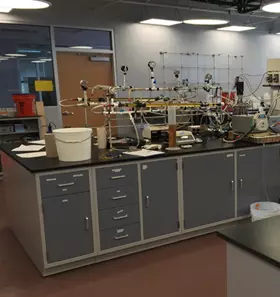

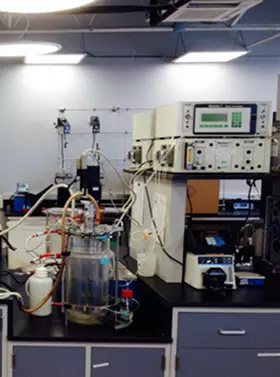

Veolia's laboratory capabilities include extensive lab or bench scale pilots to reduce risk in technology selection and also to help identify solutions to ongoing operational problems. Through lab pilot studies, Veolia clients can be provided predictive simulation data on both new and existing treatment processes. This approach identifies the most effective solutions for each customer's specific treatment needs.

Veolia Water Technologies is able to provide comprehensive water and wastewater characterizations and lab piloting. This includes basic testing for total suspended solids (TSS), Biological or Chemical Oxygen Demand (IBOD/COD), nutrients ( such as Nitrogen, Phosphorus, and Sulfur); as well as metals. Our lab capabilities also include gas chromatography, bio-methane potential testing, biomass analysis, as well as filterability and toxicity.

Our lab is also equipped with several pilots. Since we execute full-scale projects consistently, we are able to bring full-scale performance results back into the lab to ensure that our lab pilots are in sync with what is actually possible in the field at full-scale.

Biological Wastewater Analysis & Piloting

Lab Tests & Analysis

- Anaerobic Treatability

- Aerobic Treatability

- Biomethane Potential Testing

- Biogas Quality Testing

- Toxicity Testing

Available Biological Lab Pilots

- Biothane® High-Rate Anaerobic Reactors

- Anaerobic Membrane Bioreactors (Memthane®)

- CSTR (Continuous Stirred Tank Reactor)

- Aerobic MBBR (Moving Biofilm Bed Reactors)

Physical/Chemical Water & Wastewater Analysis & Piloting

Lab Tests & Analysis

- TSS (Total Suspended Solids)

- Coagulation / Flocculation

- pH

- Color

- Conductivity

- Nutrients

- Other characteristics as needed

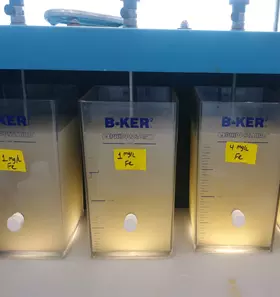

Available Physical/Chemical Lab Pilots

Filtration & Evaporation Pilots

Available Filtration Lab Pilots

- Reverse Osmosis (RO)

- Nanofiltration

- Ultrafiltration

- Vacuum Filtration

- MMF (Multimedia Filtration)

- Miscroscreen Filters (Hydrotech Drum & Disc Filtration)

- Evaporation (EVALED®)

The Philip J. Stewart Technology Center is one of Veolia’s many research facilities around the world. This facility specializes in the testing and R&D efforts, related to Veolia’s HPD® Evaporation and Crystallization technologies.

This 50,000 ft²/4,645 m² complex is home to the industry’s widest array of testing equipment that directly contributes to:

- Testing support each unique project and customer requirements

- Project development for FEED or phased engineering contracts for large, complex installations

- Validation of the process to provide the confidence that the commercial installation will perform as designed

- Development of proprietary, first-of-a-kind process designs

- Process guarantees

Analytical Testing

The range of in-house analytical capabilities is critical to understanding the project chemistry and its impact on the subsequent process design. Analysis of customer samples is generally the basis, which supports all other phases of evaluation.

The following array of analytical tests are routinely performed:

- Atomic absorption

- Gas chromatography

- Rheometry

- Inductive coupled plasma

- Total organic carbon

- Crystal size distribution

- Polarized light microscopy

- Wet chemistry / gravimetric procedures

Bench-Scale Testing

An in-depth understanding of each customer’s chemistry is critical to ensure that each unique system will perform as designed. Veolia's bench-scale testing capabilities provides excellent characterization of specific chemical behavior and often reveals the necessary information required to transition directly to a commercial design.

Characteristics determined during bench-scale testing are:

- Condensate quality

- Boiling Point Rise (BPR)

- Foaming or fouling tendencies

- Crystal size and habit data

- Crystal purity versus mother liquor contaminant concentration

- Characteristics of crystal impurities

- Vapor/liquid equilibrium data

- Physical properties (specific gravity, viscosity, specific heat)

- Solubility and phase diagrams

- Crystal habit modification

- Crystallization kinetics

Mini-Works

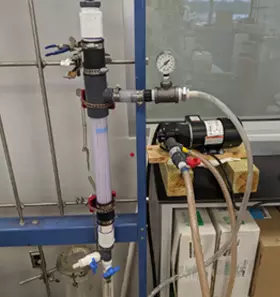

Veolia maintains a wide range of smaller-scale equipment called "Mini-Works" that effectively predicts fouling potential, investigates heat transfer performance, and measures fluid dynamics.

Testing at this scale is particularly useful for greenfield projects where there is a limited amount of samples available for pilot-scale evaluation or when shipping limitations are a concern.

Pilot Scale Testing

Design Validation to Create Confidence

Extensive pilot testing capabilities provide a "proving ground" for each specific system design during project development. Veolia's facilities contain a wide array of large-scale evaporators and crystallizers that are used to test and validate process solutions designed for commercial-stage production.

The pilot test setup can utilize ancillary equipment found in a full system to essentially replicate a commercial installation and provides thorough identification of potential upstream and downstream issues.

This unique capability is also an excellent tool for determining possible performance enhancements and the evaluation of cost-effective approaches to the process.

Specific objectives for pilot-scale tests may include:

- Obtaining heat transfer data to ensure optimum design

- Determination of the expected fouling rate during commercial operation

- Producing sufficient amounts of commercially pure product for distribution to potential end customers for determination of its market value

- Establish the amount of purge required to achieve the desired purity

- Verify the viscosity of solutions at various concentrations versus temperature

- Determining the impact of wash water quantity on crystal purity

- Verify product control stability