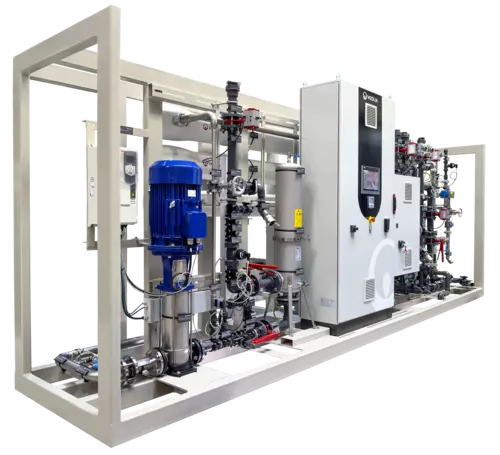

High-purity deionized water for power generation, including boiler feed and turbine injection. Terion® combines high-recovery reverse osmosis and continuous electrodeionization in a single-skid unit.

Overview

How does Terion work?

Terion produces high-purity water in a deionized water production process using reverse osmosis (RO) and electrodeionization.

Pre-treated boiler feed water first passes through a 5 micrometers (µm) cartridge filter in the Terion unit, which protects the reverse osmosis membranes from excess solid matter. The water then passes through the high injection and low energy RO membranes removing organics and dissolved salts, before polishing takes place via high-performance electrodeionization stacks.

Where required, two inlet injection points can ensure easy pretreatment conditioning. A chemical-free alternative is possible using a degasser membrane for CO2 removal, along with pretreated softened water.

Depending on the inlet water quality and treated water target parameters, Terion is available in up to five skid-mounted units ranging from 5.1 cubic meters per hour (m3/h) to 52.7 m3/h in standard and premium versions.

What are the advantages of Terion?

Terion removes over 99.9% of dissolved inorganics and over 99% of large dissolved organics for deionized water production, meeting the most stringent specifications — up to 18 megaohm (MΩ-cm) — for silica, sodium, potassium and total organic carbon levels.

As well as meeting these high-purity water and reverse osmosis recovery rates, Terion is cost-effective due to low installation and operating costs with a short lead and delivery time. Each unit is pre-assembled and tested off-site and is 100% containerized to allow for quick installation and plug-and-play start-up efficiency.

The system also has a standardized design, which is easily duplicable without compromising operation reliability. With its modular frame, Terion takes advantage of common components and piping layouts across different models to harmonize skid configuration to meet the customer's needs.

This leads to high-performance deionized water production with a near-continuous operation, requiring no stoppage, as there is no need for regeneration of chemicals during the electrodeionization stage.

Features and benefits

Water quality and performance

- Designed to produce deionized water up to 18 MΩ-cm meeting low levels of conductivity, silica, sodium, total organic carbon and potassium.

- Salt rejection rate via the high-pressure membranes is greater than 99.5%.

- Near continuous production process with no need to stop for chemical regeneration.

- Proven generation of continuous electrodeionization (CEDI) to enhance performance.

System design and features

- Plug-and-play system suitable for transport in a container, allowing for short lead, installation and start-up times.

- Pre-filter reverse osmosis protection.

- Two chemical injection points only with no dosing set.

- Frequency-controlled variable speed pumps save up to 50% of electrical power versus conventional systems.

- Ready for manual cleaning in place (CIP).

- Individual power supplies for each CEDI module to ensure high reliability.

Options

- Co₂ membrane degasser including a blower for units from 25 m³/h to 50 m³/h.

- Feed water pH probe.

- Automatic valve for reverse osmosis flushing with permeate.

- Smaller units, adjusted flows and a real plug-and-play design.

Control and monitoring

- Hubgrade™ enabled.

- Human machine interface (HMI) control panel with programmable logic controller (PLC) for remote monitoring and control.

Testing and certification

- Factory acceptance tests (FAT) including whole effluent toxicity (WET) tests.

Applications

Services

Local after-sales service and support teams offer preventative and corrective maintenance programs to ensure the long-term, efficient operation of installed plants.

Product range and resources

Terion® S

Combining single-pass reverse osmosis and continuous electrodeionization, Terion S produces high-grade deionized water meeting the highest global laboratory, power and industrial standards.

Contact

The integration of reverse osmosis and electrodeionization offers the optimal solution for achieving ultrapure water quality. Our Terion product line is unparalleled in its ability to achieve high ion removal efficiency, eliminating the need for hazardous chemicals typically used in resin deionization. This robust product can also feature a degasser option for enhanced performance and can be paired with a wide array of pretreatment possibilities to accommodate any type of feedwater. This highly effective range is a key asset in our portfolio.

Pierre Girodet

Technical director at Veolia Water Technologies

Contact Pierre through his LInkedIn account

FAQ about Terion®

What is demineralized water?

Demineralized water is water that has had its mineral ions removed. These minerals typically include ions of calcium, magnesium, sodium and other positively charged ions (cations) as well as negatively charged ions (anions) such as chloride, sulfate and bicarbonate. The process of demineralization involves the use of physical or chemical methods to eliminate these ions from the water, such as reverse osmosis.

Demineralized water is used in various industrial applications, laboratories, and certain manufacturing processes where the presence of minerals could interfere with the desired outcome or cause damage to equipment.

What is electrodeionization?

Electrodeionization is a water purification process that combines ion exchange and electrodialysis to produce high-purity water. This technology is often used for applications where high-purity water is required, such as in the pharmaceutical, semiconductor, and power generation industries and is often used as a final polishing step in water treatment systems.

What is reverse osmosis?

Reverse osmosis is a water purification process that uses a semi-permeable membrane to remove ions, molecules and larger particles from water. It is mostly used in desalination, wastewater treatment, and other applications where purification, water recovery and water reuse are necessary. In a typical system, water is pressurized and forced through the membrane, separating contaminants from the clean water.

Why is reverse osmosis important?

Reverse osmosis is important for its ability to purify water, remove contaminants and make water suitable for various applications, and it plays a crucial role in addressing water quality and scarcity challenges in different sectors. For example:

- Water purification

Removal of impurities: Reverse osmosis effectively removes a wide range of impurities from water, including contaminants such as dissolved salts, minerals, heavy metals, bacteria, viruses, and other pollutants. This results in high-purity water.

- Desalination

Salt removal: Reverse osmosis is a critical technology for desalination, the process of removing salt from seawater to make it suitable for drinking and irrigation. As freshwater resources become scarcer, desalination through reverse osmosis plays a crucial role in providing a sustainable source of drinking water.

- Industrial applications

Process water: Many industries rely on reverse osmosis to produce high-purity water for various manufacturing processes. This includes applications in electronics, pharmaceuticals, food and beverage production, and power plants.

- Wastewater treatment

Reclamation: Reverse osmosis can be part of wastewater treatment processes, helping to reclaim and create a water reuse solution for non-potable purposes. This can contribute to water conservation and reduce the environmental impact of wastewater discharge.